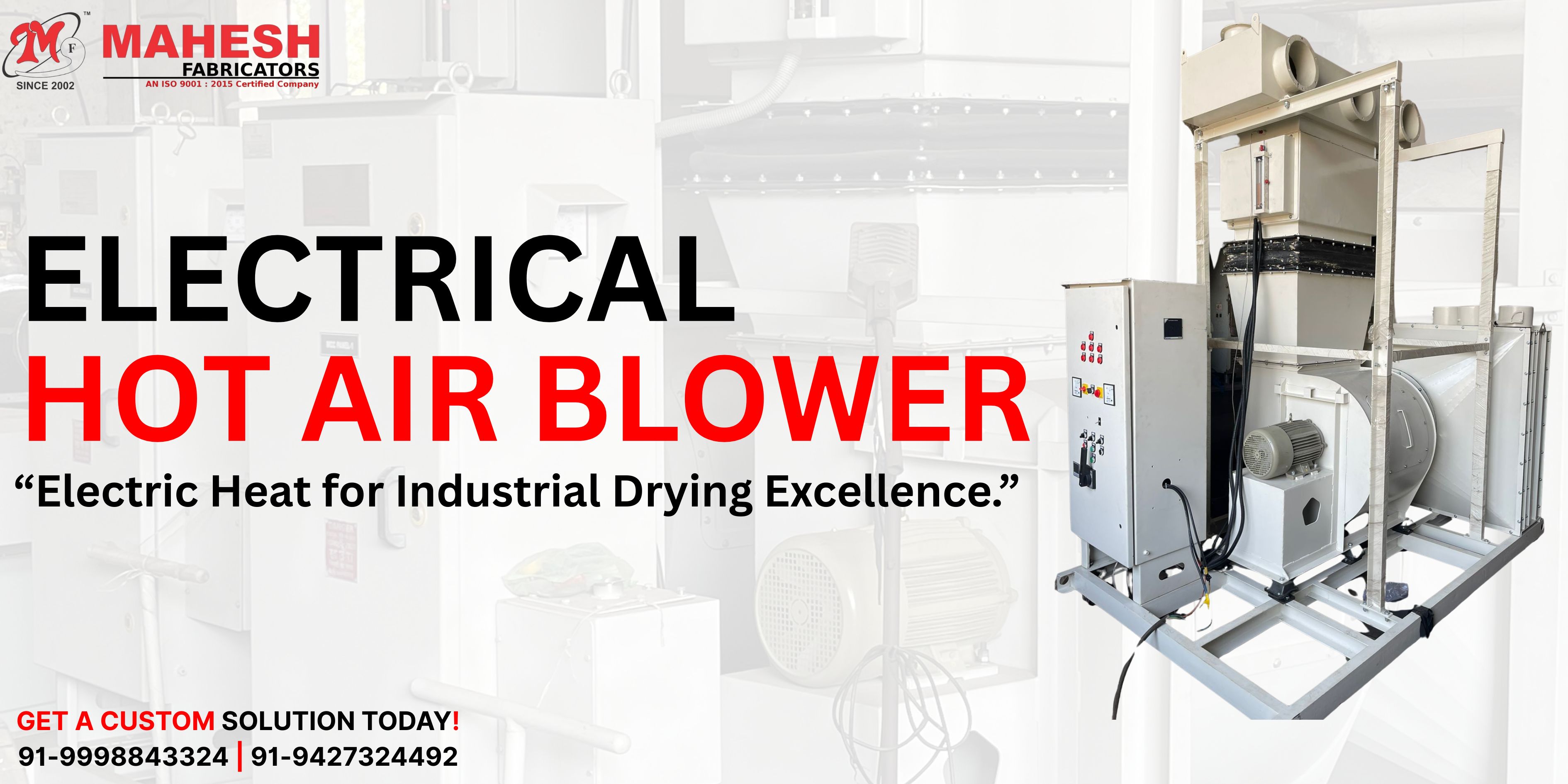

Moisture Removal Hot Air Blower Manufacturer

Description:

A Moisture Removal Hot Air Blower is an industrial drying system designed to deliver high-temperature airflow for eliminating surface and internal moisture from materials or components. It is widely used in pre-processing, post-washing, packaging, and assembly stages across multiple industries where moisture can affect quality, performance, or shelf life.

Where It’s Used:

Food processing plants (before packaging)

-

Pharmaceuticals (tablet drying)

-

Electronics manufacturing (PCB drying)

Foundries and metal finishing shops

-

Textile industries (fabric and yarn drying)

-

Printing industry (ink drying)

Uses:

-

Removing moisture from plastic resins before extrusion or molding

-

Drying food ingredients or packaging films

-

Eliminating water from surfaces after industrial cleaning

-

Improving adhesion by ensuring dry bonding surfaces

-

Enhancing powder coating or painting results

-

Conditioning air and environments in sensitive processes

Applications and Benefits:

Applications:

-

Injection moulding and extrusion line prep

-

Powder coating and painting lines

-

Conveyor drying systems

-

Food-grade drying tunnels

-

Pharma cleanroom processes

-

Lab and R&D equipment

Benefits:

-

Fast, uniform drying with controlled temperature

-

Prevents moisture-related defects (e.g., bubbles, warping)

-

Energy-efficient and cost-saving

-

Enhances product quality and operational throughput

-

Portable or inline options available

-

Reduces drying time compared to ambient or natural drying

Key Features:

-

High airflow rate with adjustable temperature (up to 300°C+)

-

Stainless steel or powder-coated casing

-

Digital temperature controller

-

Compact design with durable construction

-

Thermally insulated to prevent heat loss

-

Option for auto shut-off and overheat protection

-

Compatible with drying hoppers or custom ducts

-

Available in single-phase and three-phase models

Suppliers:

Vijay Heat Industries – Ahmedabad

Vraj Engineers – Rajkot

-

Neotech Energy Systems – Mumbai

FAQs:

-

What is a moisture removal hot air blower used for?

? It removes moisture from surfaces or materials using controlled hot airflow. -

What industries use these blowers?

? Plastics, food, pharma, auto, textiles, electronics, and more. -

Can it be used with drying hoppers?

? Yes, it integrates seamlessly with plastic drying systems. -

What is the temperature range?

? Typically 60°C to 300°C, depending on the model. -

Is it energy-efficient?

? Yes, modern models offer low power consumption with high output. -

Are portable models available?

? Yes, both fixed and mobile units are available. -

Does it require maintenance?

? Minimal – periodic cleaning of air filters and calibration checks. -

Can it be customized for specific industries?

? Absolutely – nozzle, temp range, and airflow can be tailored. -

What is the typical airflow rate?

? Ranges from 100 CFM to 1000+ CFM based on need. -

Is after-sales support provided?

? Yes, top manufacturers offer AMC, spares, and on-site service.

Why Choose Us?

ISO-certified manufacturing

Precision-engineered for consistent heat output

Customization available for your process line

Rugged build for long-term use

Energy-efficient solutions with ROI focus

Prompt support & nationwide shipping

Trusted by 1000+ industries pan-India