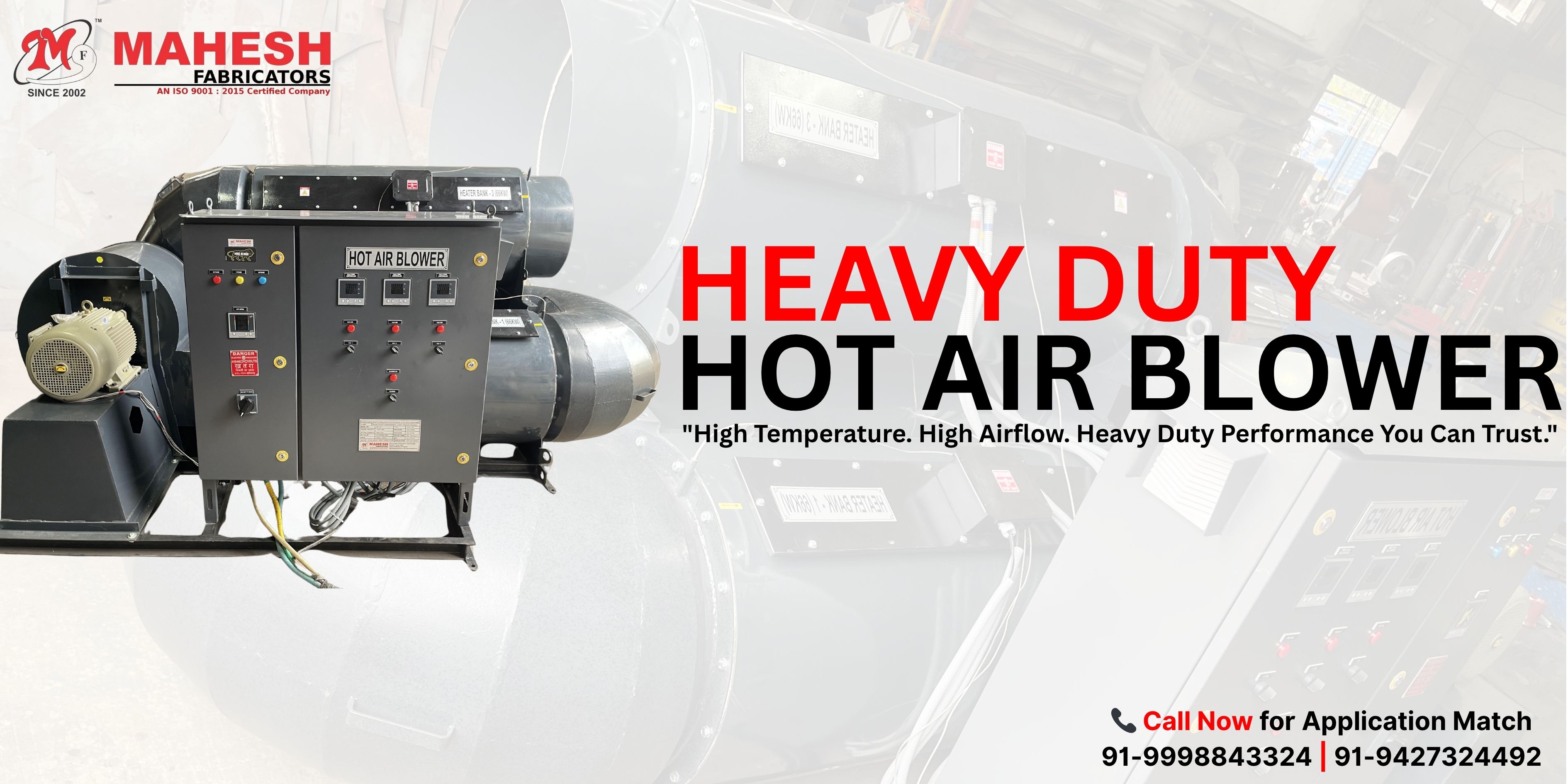

Moisture Removal Blower System Manufacturer

Best Description:

A Moisture Removal Blower System is a high-efficiency drying unit designed to eliminate moisture from surfaces or products using high-velocity hot or ambient air. It is commonly used in industrial and commercial setups where rapid, non-contact drying or dehumidifying is essential—especially post-washing, coating, or molding processes.

As a leading manufacturer of moisture removal blower systems, we supply robust, energy-efficient, and maintenance-friendly solutions suitable for varied industries like packaging, plastics, food processing, pharmaceuticals, and automotive.

Importance:

-

Prevents moisture-related damage and contamination

-

Improves product surface quality and lifespan

-

Reduces drying time, boosting productivity

-

Ensures consistent product finish and hygiene

Applications:

-

Plastic Molding Industry: Drying bottles, containers post-wash

-

Food Processing: Drying cans, jars, vegetables before packaging

-

Automotive Sector: Moisture removal from metal parts before painting

-

Pharmaceuticals: Removing moisture post-cleaning of equipment

-

Electronics & Electricals: Drying PCB components or enclosures

Key Features:

-

High-Speed Centrifugal Blowers

-

Adjustable Nozzle Arms or Air Knives

-

Optional Heating Element (for hot air drying)

-

Noise-Reduced Motor and Housing

-

Power Range: 1 HP to 20 HP

-

Air Output: 500 – 3000 CFM

-

Integrated Filter for Clean Air Supply

-

Energy-Efficient Design with VFD options

How It Uses Material / Works:

The system consists of:

-

A centrifugal or regenerative blower to generate high-velocity airflow

-

Flexible air ducts, air knives or nozzles aimed at the product surface

-

Optionally, a heater unit for generating hot air

-

Moisture is blown off or evaporated instantly, drying the item completely

-

In some setups, exhaust filters collect the displaced moisture-laden air

Materials like SS304 or powder-coated MS ensure durability in humid or chemically reactive environments.

FAQs with Detailed Answers

1. What is a moisture removal blower system used for?

It’s used to remove surface moisture or humidity from products or parts after processes like washing, molding, rinsing, or coating. By using high-velocity air (hot or ambient), it enables quick and uniform drying without physical contact.

2. Where is this system commonly used?

This system finds use in:

-

Plastic molding plants (for drying bottles/containers)

-

Automotive factories (for metal part drying)

-

Food plants (to dry produce before packaging)

-

Electronics (drying delicate components post-cleaning)

3. What type of blower is used in these systems?

Typically, centrifugal blowers or regenerative blowers are used.

-

Regenerative blowers are ideal for continuous, dry air applications

The choice depends on airflow, pressure, and space constraints.

4. Can this system be integrated into an existing production line?

Yes. Our blower systems are designed to be modular and customizable, allowing easy integration with:

-

Conveyor belts

-

Spray booths

-

Assembly lines

Mounting arms or adjustable ducts enable flexible configurations.

5. Is it suitable for both hot air and ambient air drying?

Yes. Systems can be designed for:

-

Ambient air (for energy-saving or heat-sensitive items)

-

Hot air (for fast evaporation or cold environments)

In hot air systems, heaters (electric or gas-fired) are used inline.

6. What is the typical power and airflow capacity?

-

Power range: 1 HP to 20 HP

-

Airflow: 500 – 3000 CFM or higher

Customized capacities are available based on drying speed, item size, and moisture level.

7. Does it require regular maintenance?

Very minimal. Maintenance includes:

-

Periodic cleaning of filters and air ducts

-

Checking motor bearings and lubrication

-

Ensuring no moisture buildup in ducts or outlets

With high-quality systems, you can expect long-term operation with low downtime.

8. Is it safe for use in hygienic or cleanroom environments?

Yes. Stainless steel models (SS304/SS316) are:

-

Corrosion-resistant

-

Easy to clean and maintain

They are widely used in pharma, dairy, and food-grade environments.

9. How is the moisture removed from the air after drying?

In closed-loop or sensitive setups, an exhaust vent or dehumidifier may be used to expel moist air from the drying zone. In most open-loop systems, air is released into the environment, especially when ambient air is used.

10. Why choose a manufacturer over a reseller?

As a direct manufacturer, we offer:

-

Customized system design for your space and need

-

Warranty and after-sales service

-

Better cost-effectiveness and technical assistance during installation and scaling

Trusted Manufacturer – Serving Across India

We are a recognized Moisture Removal Blower System Manufacturer, serving sectors like food, plastics, pharma, textiles, and engineering across Ahmedabad, Mumbai, Delhi, Hyderabad, and Chennai.

For Enquiries and Technical Support:

Email: info@maheshfabricators.com

Phone: +91-9427324492 +919998843324

Website: https://maheshfabricators.com/