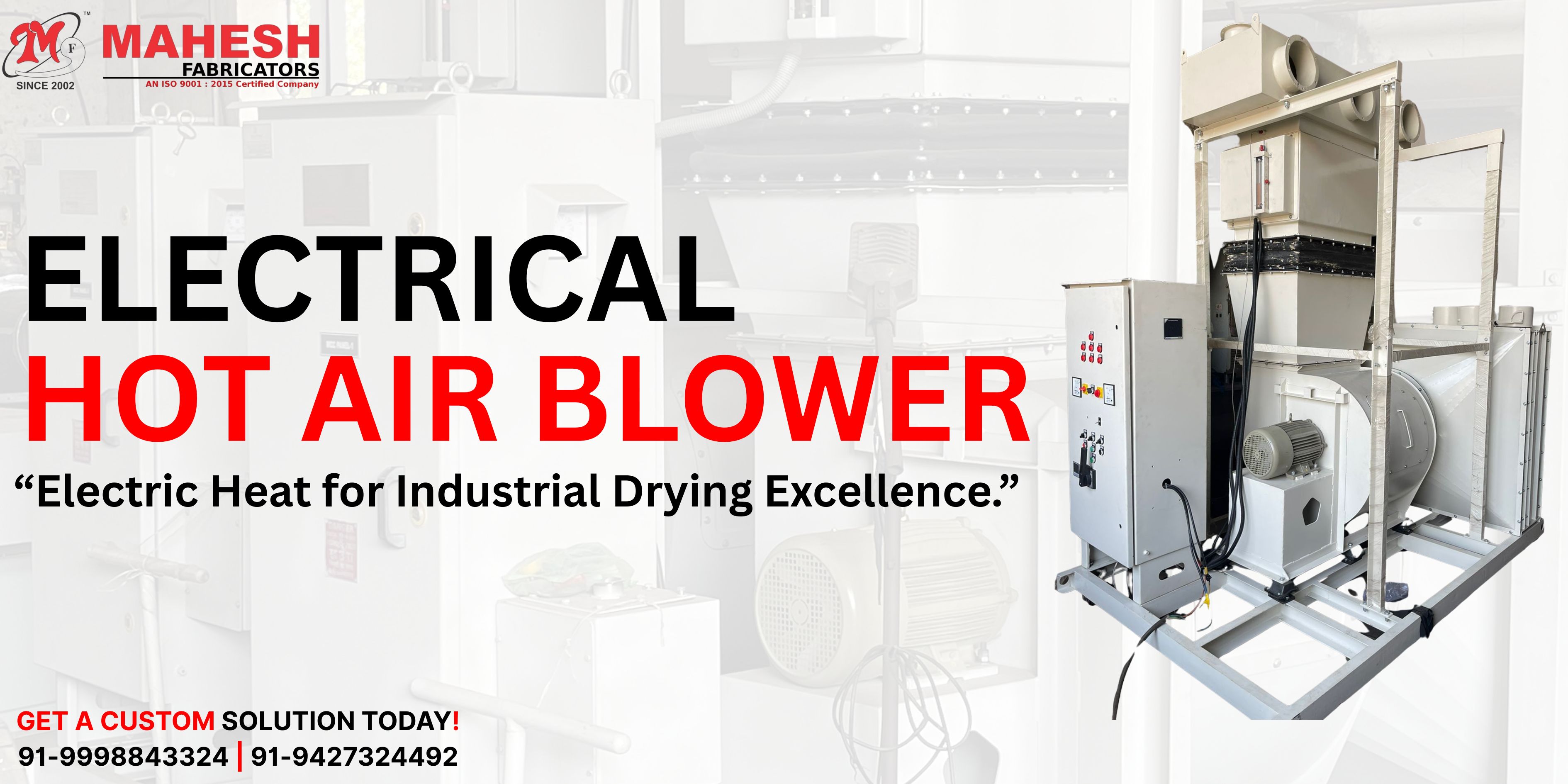

Centrifugal Fan Type Heater Blower

Description

A Centrifugal Fan Type Heater Blower is a high-efficiency heating system that uses a centrifugal fan to blow hot air across specific areas or materials. It combines air movement and heating in one unit, ideal for industrial drying, ventilation, or heat treatment applications.

The centrifugal fan delivers high-pressure airflow, while electric or gas heaters raise air temperature. These blowers are widely used in factories, paint booths, dryers, ovens, and HVAC systems, offering consistent heat output and improved process control.

Where It’s Used

-

Industrial hot air ovens & dryers

-

Paint booths and powder coating plants

-

Textile, paper, and plastic drying lines

-

Machinery pre-heating or dehumidification systems

-

Automotive part drying or heat curing

-

Laboratory or pharma-grade heating environments

-

Duct heaters and HVAC systems

-

Chemical processing and reactor heating

-

Tool room and die heating

-

Brick, ceramic, and glass manufacturing

Uses

-

Heating and drying of materials or surfaces

-

Curing paints, adhesives, and coatings

-

Maintaining controlled temperature environments

-

Blowing hot air into closed systems or ducts

-

Moisture removal and air circulation in industrial areas

-

Speeding up drying in batch or continuous processes

-

Dehumidifying storage or pre-production spaces

Importance

-

Provides precise temperature control in critical applications

-

Ensures uniform heating and airflow for industrial processes

-

Enhances energy efficiency by combining fan and heater

-

Reduces process time, boosts productivity

-

Supports safe and reliable heating for sensitive operations

Significance

-

Essential for non-contact heating in industrial settings

-

Reduces manual intervention and ensures process automation

-

Available in custom air flow (CFM) and heating capacities

-

Crucial in meeting industrial drying and curing standards

-

Reliable in dusty, high-humidity, or high-temp conditions

FAQs

-

What is a centrifugal fan type heater blower?

– It’s a blower that combines high-pressure air movement with heating, used for drying or heating spaces/materials. -

Where is it commonly used?

– In industrial drying ovens, paint booths, HVAC ducts, and process lines. -

What is the temperature range?

– Typically from 50°C to 300°C, depending on design and heating element. -

Is it electrically operated or gas-powered?

– Available in both electric and gas-fired heating versions. -

What’s the airflow capacity range?

– From 500 CFM to over 20,000 CFM, based on application. -

Can it be used in ducting systems?

– Yes, it’s often integrated into custom air ducts or chambers. -

Is it energy efficient?

– Yes, especially when fitted with thermostats and speed controllers. What materials are used in construction?

– Typically mild steel or stainless steel with high-temperature insulation.-

Does it need regular maintenance?

– Minimal maintenance; occasional motor checks and filter cleaning are sufficient. -

Can it be customized?

– Yes, air volume, pressure, and heater type can all be customized.