Centrifugal Air Blower for Heating

A Centrifugal Air Blower for Heating is a mechanical device that moves air at high pressure using centrifugal force. It plays a crucial role in supplying hot air in industrial heating applications, providing consistent airflow for furnaces, dryers, heat exchangers, ovens, boilers, and hot air blowers.

Made from mild steel or stainless steel, these blowers are designed for thermal durability, energy efficiency, and long-term performance, handling temperatures up to 300°C or more when paired with heat-resistant insulation.

Where It's Used

-

Hot Air Drying Systems

Food Processing Ovens

-

Paint & Powder Coating Lines

-

Chemical & Pharmaceutical Reactors

Detergent & Soap Manufacturing

-

Textile Drying & Curing Units

Uses

-

Circulating hot air uniformly across heating chambers

-

Blowing air through heat exchangers or heating coils

-

Removing moisture, fumes, or vapors during processing

-

Assisting combustion in fuel-based heating systems

-

Enhancing energy transfer in industrial drying units

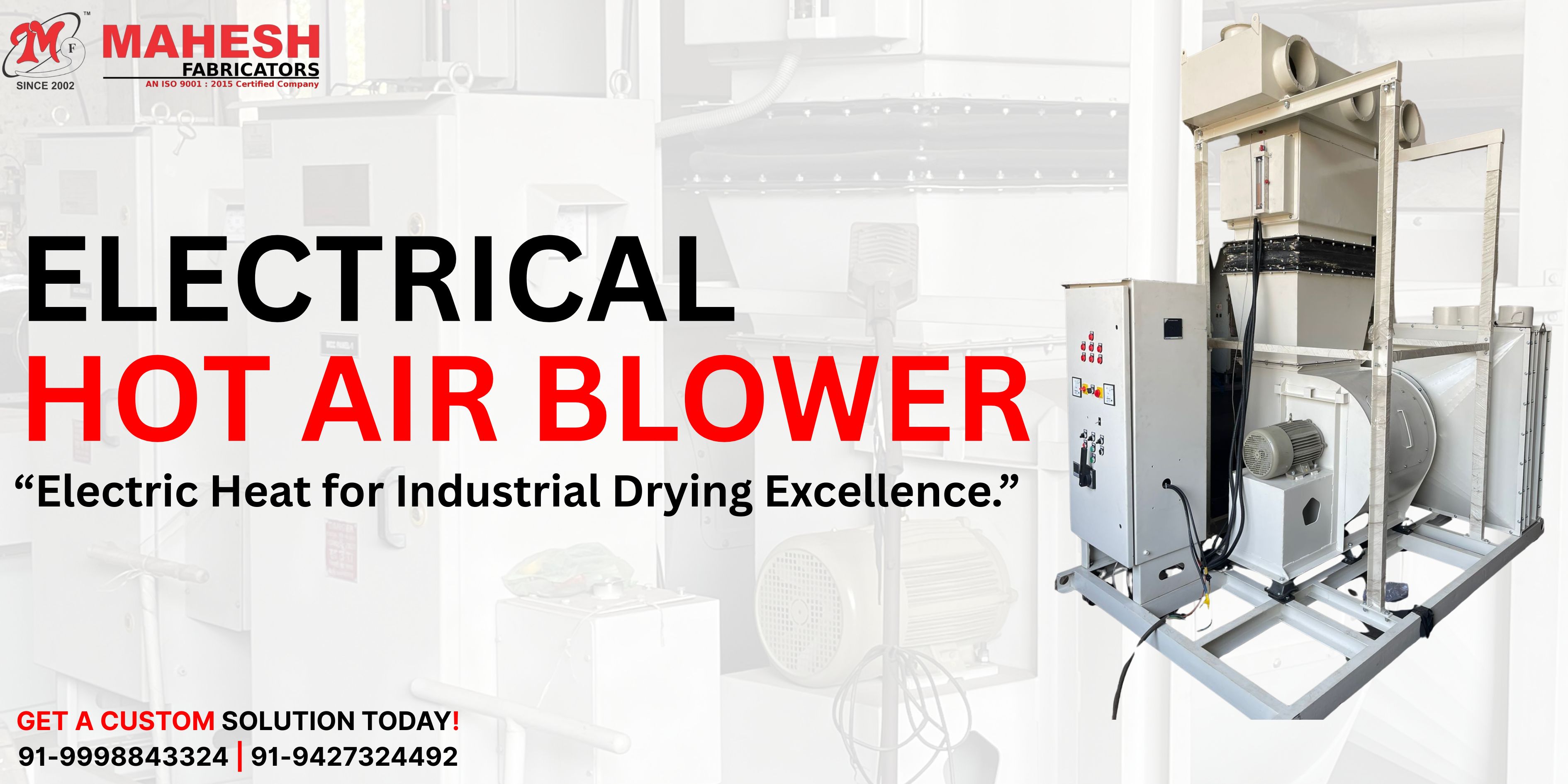

Description

Centrifugal Air Blowers consist of an impeller fan, air inlet, and discharge housing designed to force air radially. When used for heating, they are combined with heating elements or hot air generators, ensuring steady and adjustable airflow with minimal loss.

They are available in:

-

Forward curved, backward curved, or radial blade types

-

Designed for high-pressure or high-volume needs

Materials used include MS, SS304/SS316, or powder-coated aluminum, with insulated housings for heat resistance.

Importance

-

Ensures efficient and even heating

Reduces processing time with faster airflow

-

Prevents overheating or hot spots

-

Increases safety in high-temperature applications

-

Reduces energy consumption with precision airflow control

Significance

-

Integral in industrial heating, drying, and combustion systems

-

Meets ISO and CE safety standards

-

Vital for productivity, quality, and process consistency in manufacturing

-

Promotes energy efficiency in heat-intensive sectors

FAQs

1. What is a centrifugal air blower for heating?

It’s a blower that forces air through heating elements or chambers, delivering hot air in industrial processes.

2. What temperature range can it handle?

Typically from 60°C to 300°C, depending on the blower model and insulation.

3. Can it be used with electric heaters?

Yes, it’s commonly paired with electric coil or gas-fired heaters.

4. Is it safe for explosive or corrosive environments?

Special flameproof and corrosion-resistant models are available on request.

5. What are the power options?

Available from 0.5 HP to 20 HP+, in single-phase or three-phase motors.

6. What type of fan blades are used?

Backward curved, radial, or forward curved depending on pressure/volume needs.

7. Can the airflow be controlled?

Yes, via dampers, VFDs (variable frequency drives), or manual regulators.

8. How is it installed?

Typically on floor mounts or duct flanges, with insulation if handling hot air.

9. What material is best for heat applications?

Stainless steel or powder-coated mild steel for high-heat durability.

10. Do you provide noise-controlled models?

Yes, low-noise or silenced housings are available for sound-sensitive applications.

Why Choose Us?

-

Leading manufacturer & exporter of industrial blowers

Heat-resistant designs with thermal insulation options

-

High efficiency, low power consumption

Export to UAE, Africa, Asia, and beyond

-

Timely delivery and expert installation